Table of contents

Table of contents

Value stream mapping vs. process mapping

Summary

In this guide, you will learn:

- Process mapping details every step; VSM gives a high-level overview.

- Process mapping focuses on operational improvements; VSM targets strategic improvements by identifying waste and lead times.

- Process maps use flowcharts and swim lanes; VSM uses specific symbols for flow.

- Both methods are complementary: process mapping refines daily tasks; VSM eliminates waste across departments.

- VSM assigns value and emphasizes lead time reduction for enhanced value delivery.

- Use VSM first for strategic alignment, then process mapping for detailed optimization.

Understanding value stream mapping and process mapping

Business process improvement can seem like a maze of confusing terms and methodologies. Two methods that often cause confusion are value stream mapping (VSM) and process mapping.

While they might appear similar at first glance, understanding their differences and uses is vital for process improvement and operational efficiency.

Definitions

Before diving into how these methodologies differ, let's first understand what each entails:

Value stream mapping is a lean management tool that helps visualize the steps needed to take from product creation to delivering it to the end customer.

The purpose of VSM is to provide a holistic view, encapsulating the journey of raw materials into finished goods, and everything in between.

This kind of visual map enables organizations to see where value is added to their processes and where there is waste that can be minimized or eliminated.

Process mapping can be applied more broadly. Virtually any type of workflow can be broken down into smaller steps — making it easier to understand contingencies and dependencies within a project or process.

It's like examining a leaf under a microscope, each vein representing a different step or decision point. With process mapping, organizations can understand the nitty-gritty of their processes, right down to each action, decision, and responsibility.

Value stream mapping vs process mapping: Differences and similarities

Value stream mapping and process mapping, while different in scope, are complementary to one another. Let's delve deeper into their unique features and overlaps.

Key features of value stream mapping

Value stream mapping goes beyond mere processes. It paints a comprehensive picture of the flow of materials and information throughout the entire value-creation process. From raw material procurement to delivery to the end customer, it covers all aspects. It also includes timelines, allowing organizations to measure lead time and processing time.

Key features of process mapping

Process mapping, meanwhile, zeros in on individual processes. It's all about detail. Every step, every decision point, every interaction is mapped out, providing organizations with a granular view of their processes.

Where VSM and process mapping overlap

Though distinct in their approach, both methods are indispensable tools for process improvement. They provide a visual representation of processes, thereby making the abstract concrete, the complicated simple, and the invisible visible.

Process map vs value stream map: Practical applications in business

Let's now turn to the practical side of things. How and when should organizations use these tools?

When to use value stream mapping

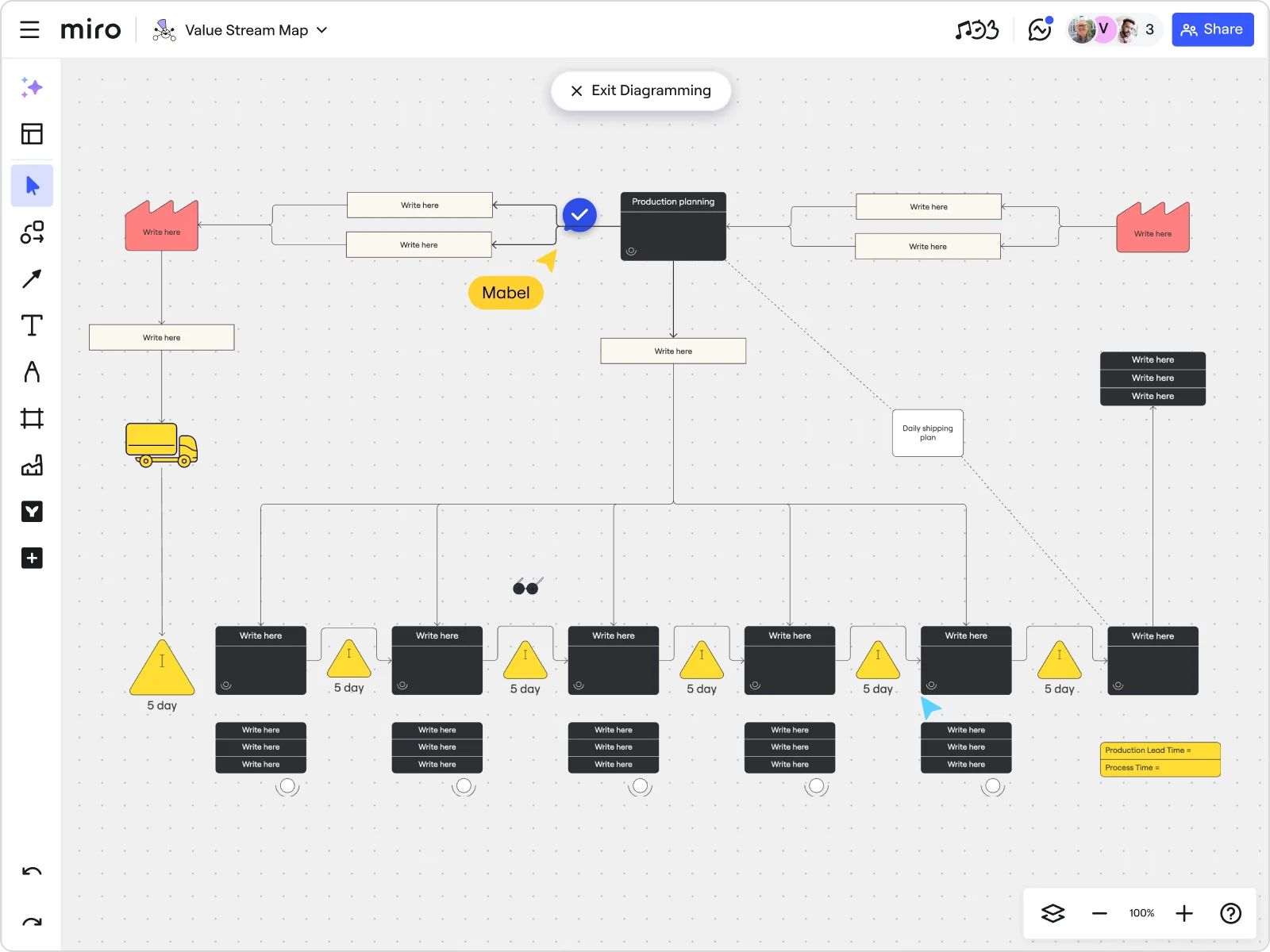

Value stream mapping is best used when you're trying to get an overview of the entire value creation process. It's particularly useful when the goal is to identify waste and improve lead times. With this bird's eye view, you can streamline processes and improve flow at a macro level by creating a value stream map. You can choose a value stream mapping template from Miro's library as a starting point to visualize your process.

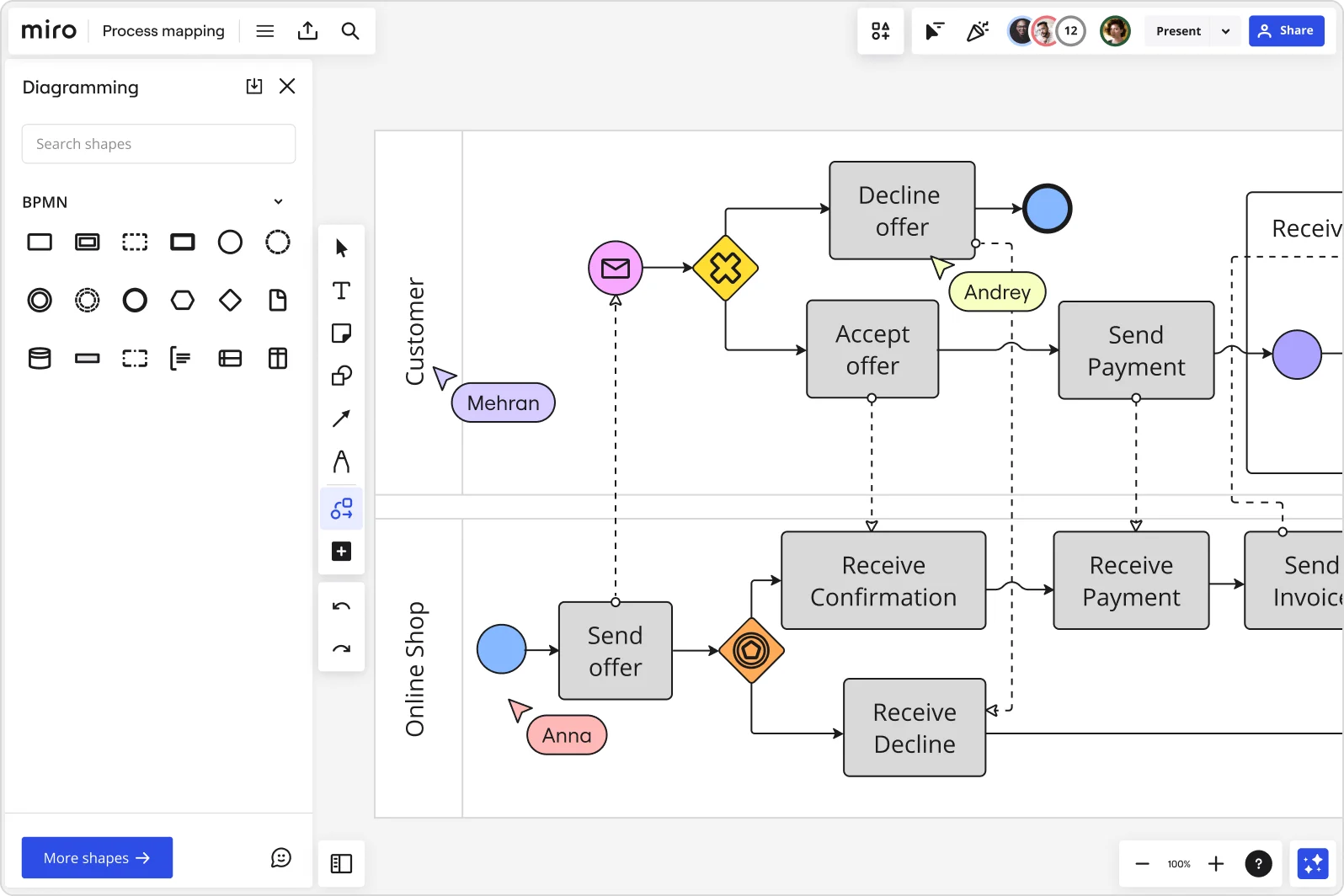

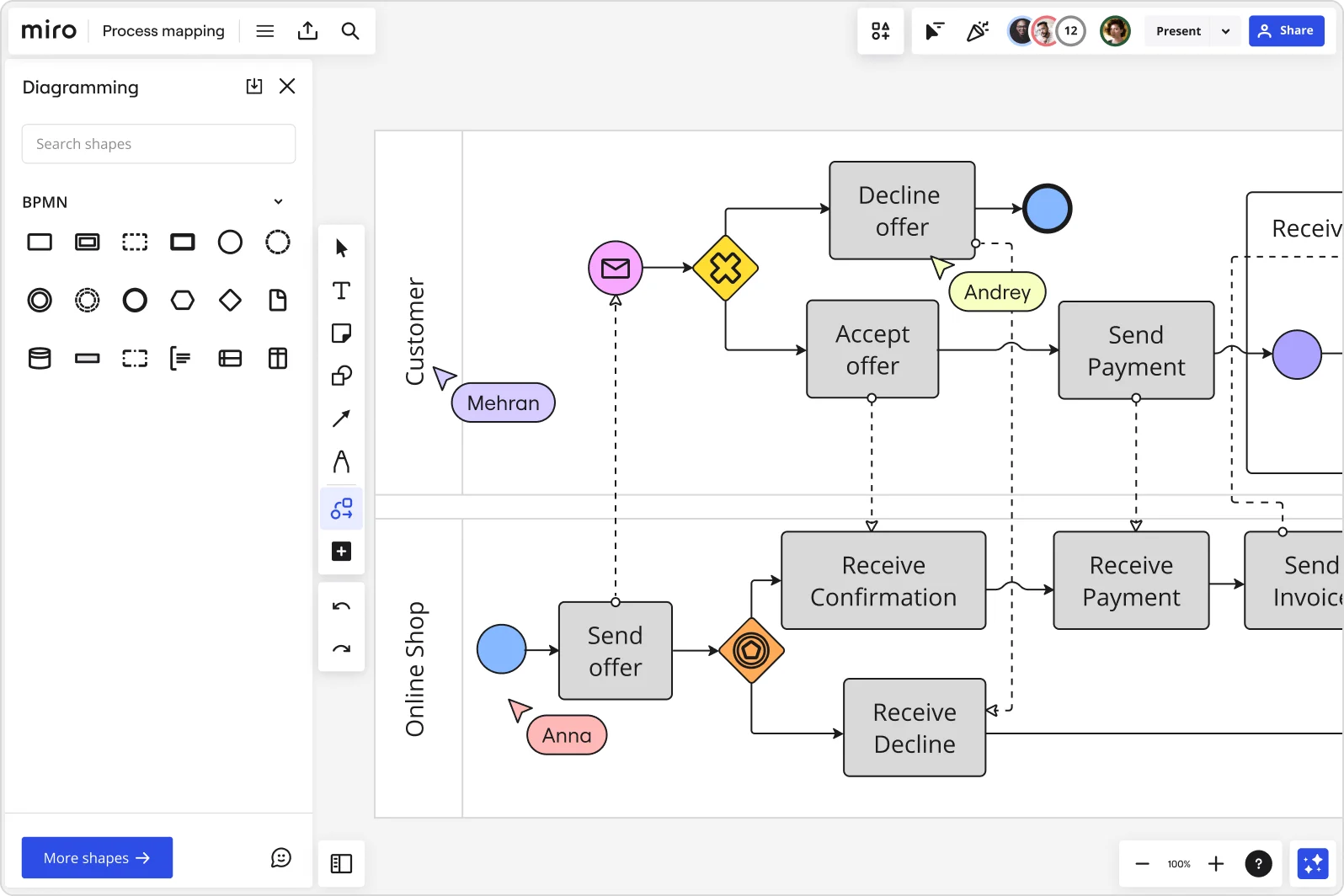

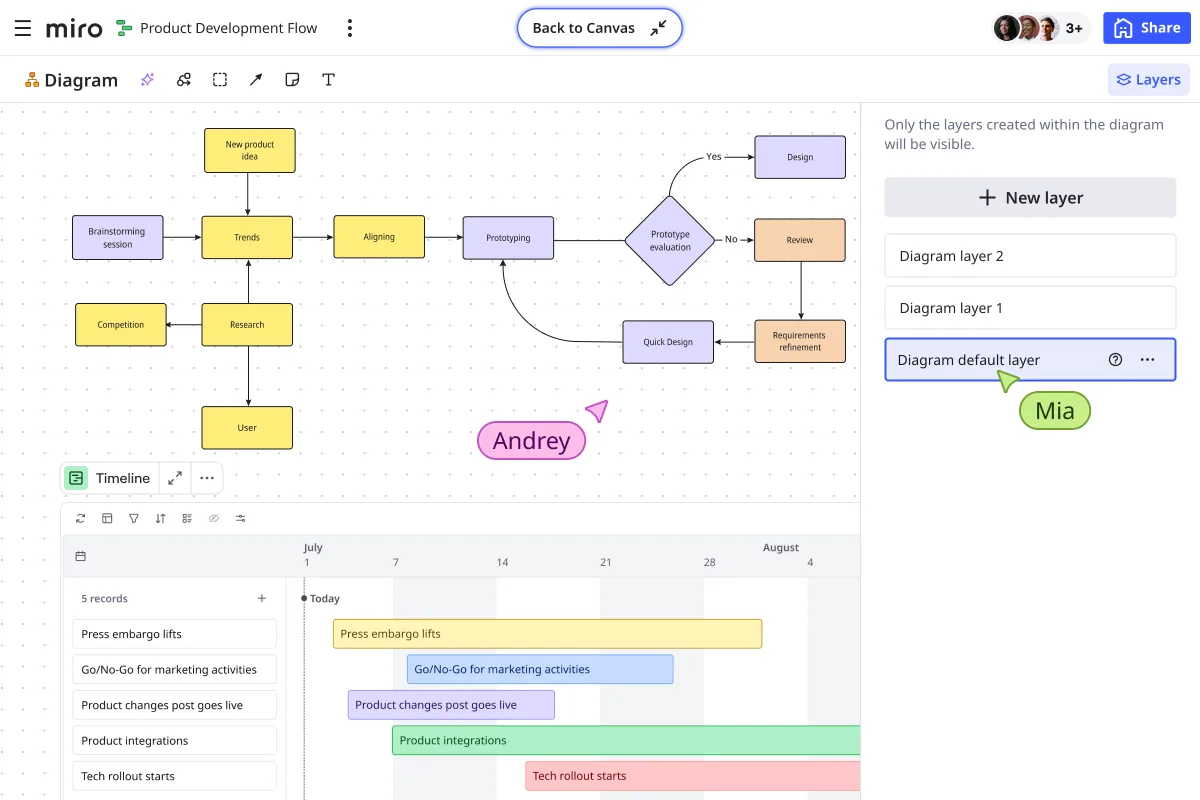

When to use process mapping

Conversely, process mapping is your go-to tool when you need to analyze a specific process in detail. Whether you're training new employees, standardizing a process, or identifying bottlenecks, making a process map can help. Use one of the ready-made process map templates from Miro to jumpstart the analysis.

Impact on business efficiency

Now that we know what value stream mapping and process mapping are, let's look at their effect on business efficiency.

How value stream mapping enhances efficiency

Value stream mapping offers a holistic view of the material and information flow. By pinpointing areas of waste and delays, it helps organizations improve their efficiency at a systemic level. The end result? Faster lead times, lower costs, and happier customers.

The role of process mapping in operational efficiency

On the other hand, process mapping shines a spotlight on individual processes. It helps uncover bottlenecks and unnecessary steps that can be eliminated or streamlined. By improving efficiency at the process level, organizations can ensure smooth operations and increased productivity.

Deciding which to choose: Value stream mapping or process mapping?

Choosing the appropriate method for your organization depends on various factors. Understanding your needs, constraints, and end goal can help guide this decision.

1) Understanding your objective

The first step in choosing between value stream mapping and process mapping is to understand your organization's objective. If your goal is to gain a high-level view of the entire system to identify systemic waste and inefficiencies, value stream mapping would be more appropriate. This tool provides a comprehensive picture of the value flow, helping organizations identify areas where waste occurs and where value is not being fully realized.

On the other hand, if your goal is to dive into the details of a specific process, process mapping would be a better fit. For instance, if you're experiencing problems in a particular process, and you need to understand the process intricacies to solve the issue, process mapping can help. This tool allows you to dissect individual processes, revealing every step, decision point, and bottleneck.

2) Considering your resources

Another factor to consider is the resources available to you. Implementing value stream mapping requires a significant investment of time and effort. You would need to gather data on every process, which could be resource-intensive. This method might not be the best fit if you're constrained by time or manpower.

Process mapping, in contrast, is less resource-intensive since it focuses on specific processes. However, keep in mind that while it might require less initial effort, process mapping can become quite complex and time-consuming as you delve into the intricacies of each process.

3) Analyzing the level of change desired

The level of change you desire in your organization also plays a role in the decision. If you're looking to transform your operations and bring about large-scale change, value stream mapping could provide the insights you need. By offering a system-wide view, this method enables organizations to undertake large-scale improvements and transformations.

However, if you're looking for incremental change or improvements within specific processes, process mapping would be more suitable. By focusing on the details, this method allows you to make targeted improvements and tweaks to optimize individual processes.

4) Deciding based on your organizational culture

Finally, your organizational culture can also influence the choice between value stream mapping and process mapping. Some organizations have a culture that embraces comprehensive, top-down changes. For these organizations, value stream mapping could align well with their culture.

In contrast, other organizations might have a culture that focuses on gradual, bottom-up improvements. In these cases, process mapping, with its focus on specific processes, might be a more comfortable fit.

Conclusion: Value stream mapping vs process mapping

In a nutshell, both value stream mapping and process mapping serve crucial roles in process improvement.

There's no one-size-fits-all answer to the question of whether to use value stream mapping or process mapping. Instead, the decision should be based on a combination of factors, including your objectives, resources, desired level of change, and organizational culture. By taking all of these factors into account, you can make an informed decision that best suits your organization's needs and goals.

Depending on the objective at hand, organizations can use these tools to gain a clear understanding of their operations, identify areas of waste, and enhance efficiency. Armed with this knowledge, you're now ready to map your way to success.

Author: Miro Team Last update: August 13, 2025