Table of contents

Table of contents

Lean project management methodology

Lean project management methodology: A quick intro

In our ever-changing business world, project management methodologies offer structure and guidance for teams to accomplish their objectives efficiently. As a framework for coordinating activities, it ensures the effective execution of projects, mitigating risks and preventing project failures.

Among the many methodologies, Lean is particularly noteworthy. Created initially for manufacturing efficiency, Lean has evolved into a versatile project management approach applicable across various industries. Today, we'll explore what Lean project management methodology is all about.

Background of Lean methodology

Lean traces its roots back to the manufacturing sector, specifically to the Toyota Production System of the 1930s. Designed to eliminate waste and optimize production, it was a groundbreaking approach that reshaped the manufacturing world.

Over time, Lean's core principles transcended their manufacturing origins, finding relevance in project management. The methodology offers a fresh perspective on achieving objectives, delivering value, and reducing waste in projects across various sectors.

Understanding Lean project management

At its core, Lean project management is a philosophy rather than merely a methodology. It is grounded on the tenet of delivering maximum value with minimum waste. This is achieved by focusing on what truly matters to the customer, streamlining processes to increase efficiency, and promoting a culture of continuous improvement.

A. Definition and basic principles of Lean project management

Lean project management can be defined as an iterative approach that focuses on reducing waste (activities that don't add value) while ensuring customer value in project processes. This customer-centric philosophy is all about producing quality results efficiently.

There are three basic principles:

Eliminating waste: This is all about identifying and removing activities that do not add value to the customer. Waste can be in the form of unnecessary meetings, excessive documentation, or even waiting time in a project's lifecycle.

Optimizing value: Value optimization focuses on activities that directly enhance customer value. It involves understanding what the customer perceives as valuable and directing resources toward those elements.

Continual Improvement: Lean project management is an ongoing journey. It encourages iterative cycles of planning, doing, checking, and acting (PDCA) to continuously improve the process and product. It seeks to foster a culture where all team members actively participate in finding better ways to deliver more value.

B. Core elements of Lean project management

Several critical elements contribute to the successful application of Lean project management:

Value-driven focus: Every project component must contribute value. If it doesn't, it is viewed as waste and is a candidate for elimination.

Respect for people: Lean believes people are the most significant resource. The methodology focuses on empowering team members, fostering a sense of ownership, and creating a collaborative environment.

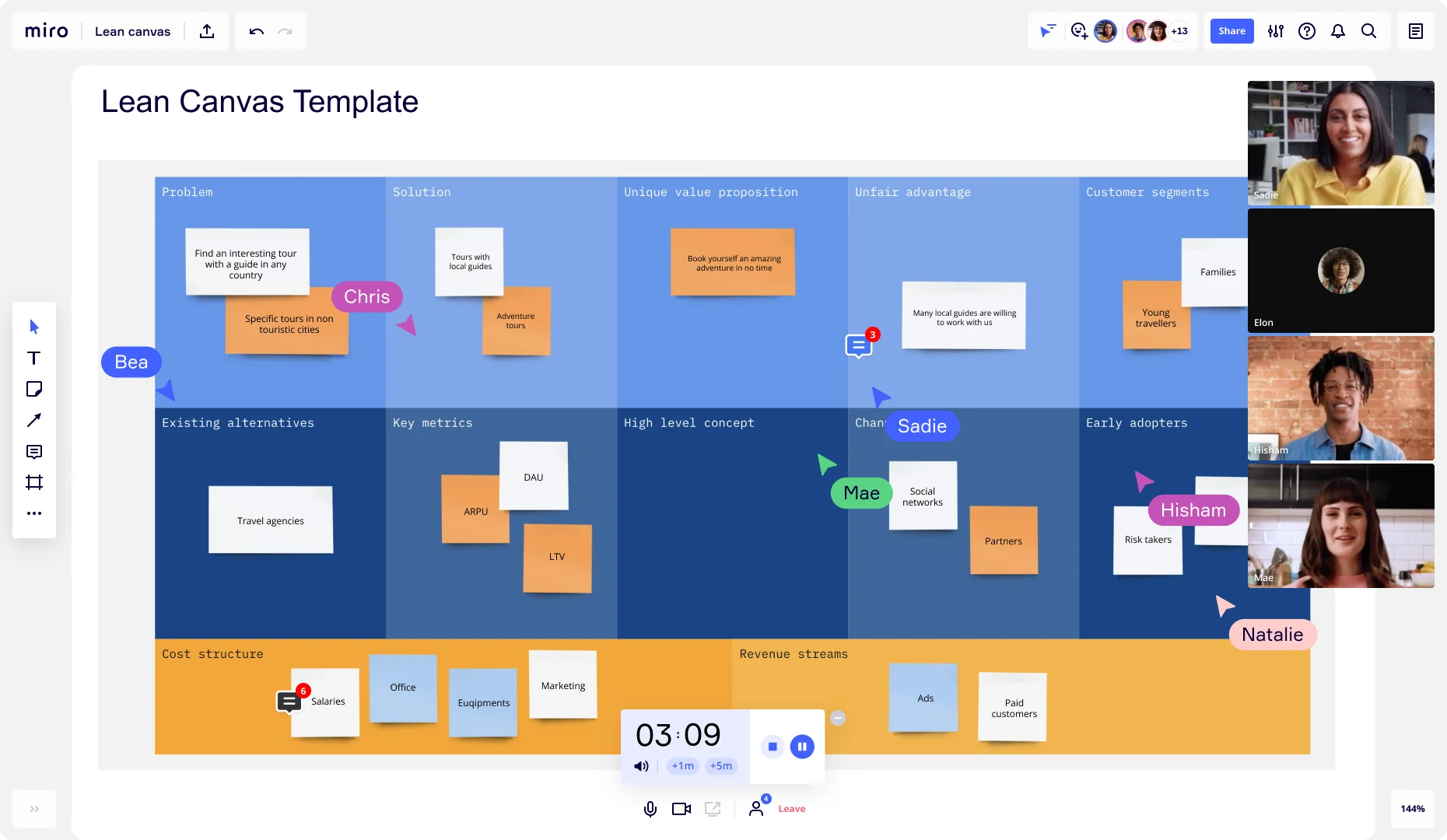

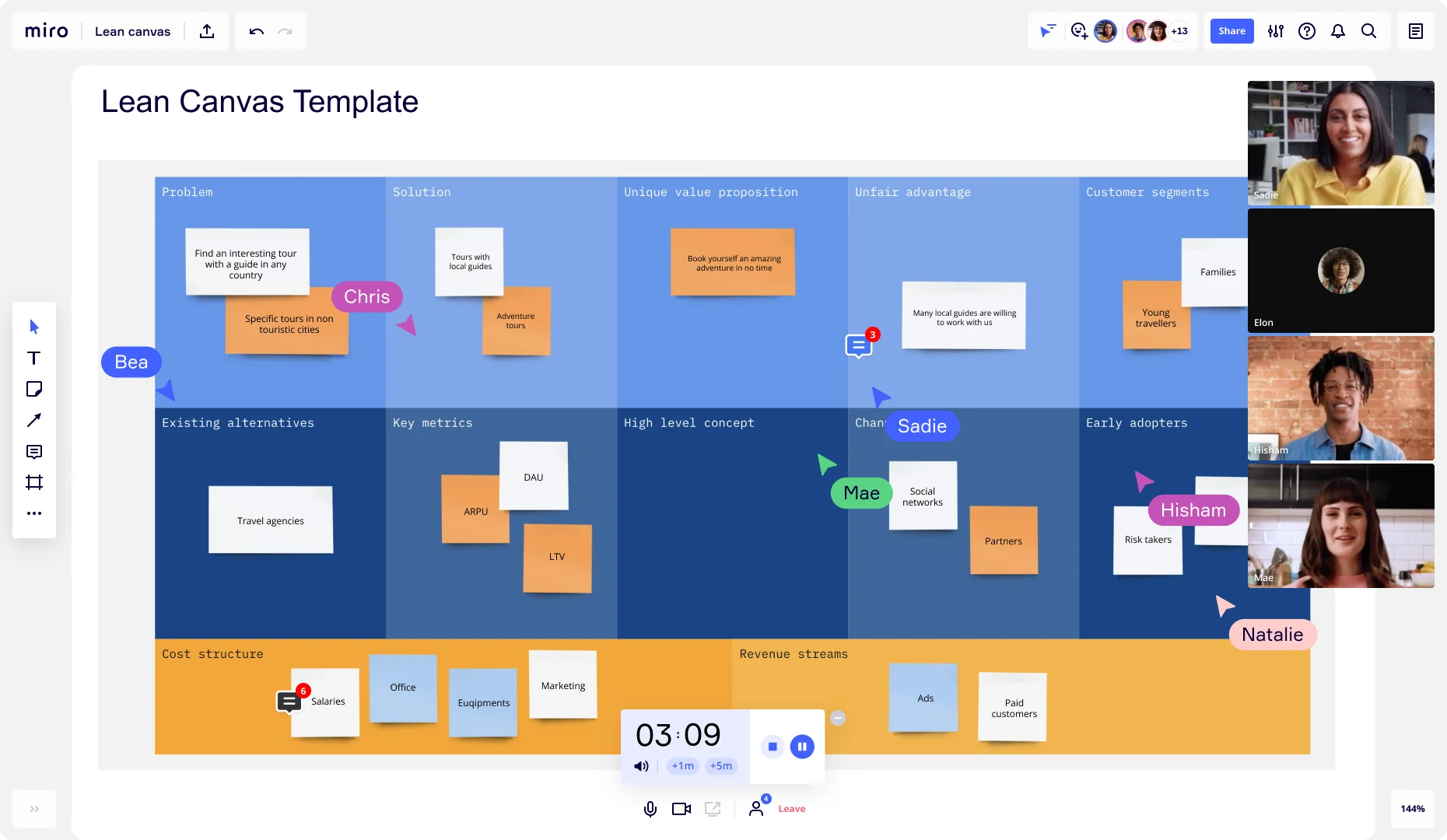

Visual management: Lean embraces transparency. Tools such as Kanban boards help visualize workflow, make clear what tasks need to be done, identify bottlenecks, and track progress.

Kaizen (Continuous Improvement): Kaizen fosters an environment of constant learning and improvement. Teams are encouraged to continuously identify opportunities for improvement and innovate solutions.

C. Understanding Lean terms

There are several key terms integral to Lean:

Value Stream: This refers to all activities, from start to finish, required to deliver a product or service to the customer.

Kaizen: A Japanese term that means 'change for the better,' Kaizen in Lean refers to activities that continuously improve all functions and involve all employees.

Just-in-Time (JIT): Companies employ an inventory strategy to increase efficiency and decrease waste by receiving goods only as needed in the production process, thereby reducing inventory costs.

Jidoka (Autonomation): This concept implies that when a problem occurs, the equipment stops immediately, preventing defective products from being produced. It also enables workers to promptly identify the issues that led to the problem.

By understanding and embracing these principles, elements, and terms, organizations can effectively implement Lean project management and create more value with less waste.

Key features of Lean project management

Lean project management is characterized by a focus on customer value, empowerment of teams, reduced production times and waste, continuous improvement, and streamlined processes. These principles facilitate better project outcomes, foster team autonomy, and ensure alignment with customer needs.

The Lean project management process

The Lean process involves five steps:

Identifying value: Understanding what the customer truly wants

Mapping the Value Stream: Tracing the product's lifecycle from inception to delivery

Creating flow: Optimizing operations for seamless process flow

Establishing pull: Shifting to a customer-driven production system

Seeking perfection: Pursuing continuous improvement to close performance gaps

Lean project management tools

Several tools aid in Lean project management. Kanban Boards visualize workflow and monitor project status. Value Stream Mapping illustrates the current process and identifies opportunities for improvement. The Five Whys technique helps identify the root causes of problems. Poka-Yoke (Mistake Proofing) prevents errors from occurring.

In the corporate world, Toyota still shines as a successful Lean implementer. At the same time, other organizations like Intel and Nike have also embraced Lean tools to enhance productivity and reduce waste.

Pros and cons of Lean project management

Lean methodology offers several advantages: waste reduction, value optimization, and continuous improvement. However, implementing Lean can present challenges like resistance to change and the requirement for a significant cultural shift within the organization.

Comparing Lean with other project management methodologies

Lean differs from other methodologies like Agile and Waterfall in its relentless focus on waste elimination and customer value. It's best suited for projects where efficiency and process optimization are key concerns. Yet, its flexible nature allows applicability across a wide range of projects.

Implementing Lean project management in your organization

Successful Lean implementation involves multiple steps, including creating a Lean-conscious culture, employee training, and leadership support. Leaders play a crucial role in fostering a Lean environment and driving the necessary cultural change.

Conclusion

Lean project management methodology offers a structured approach to project execution, focusing on delivering maximum value with minimal waste. As you delve deeper into Lean, you'll discover a philosophy dedicated to continuous improvement and customer satisfaction. While the Lean journey might be challenging, its potential rewards make it worthwhile.

References

This article's information was sourced from various academic and non-academic references, including James P. Womack and Daniel T. Jones' "Lean Thinking," Jeffrey K. Liker's "The Toyota Way," and Mike Rother's "Toyota Kata."

Lean project management methodology is more than a set of tools or procedures; it's a mindset centered on value creation and waste elimination. With its unique approach to project management, Lean has the potential to transform your organization's project execution and drive remarkable results. It's a journey of continuous learning and improvement - one that I hope this article has inspired you to begin.